The Problem

- Low service life of conventional wear parts

- High production downtime

- High crusing / grinding cost

- High maintenance cost

- Deteriortion in product efficiency

- Huge waste generation

Solution

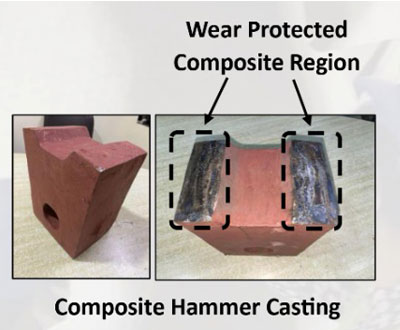

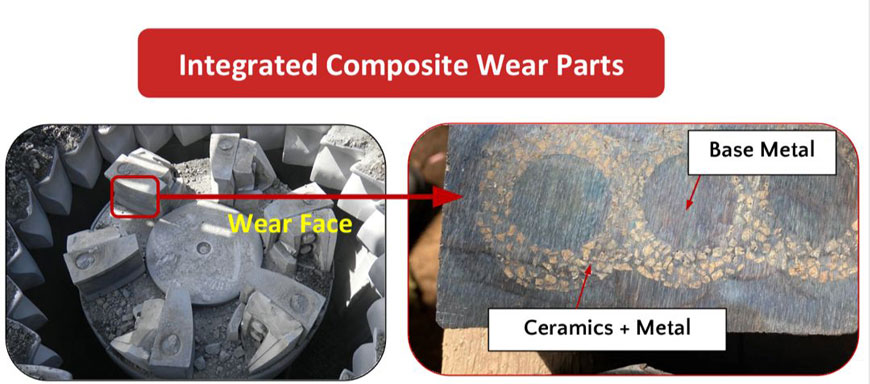

Integrated Composite wear parts

Our composite wear parts are made by infusing hard ceramic core into metal castings. This innovative approach combines the hardness of reinforced ceramics with the flexibility of a ductile metal martix, resulting in superior wear resistance properties.

| Material | Hardness (in HV) |

|---|---|

| Ceramic | 1400-1600 |

| Metal Matrix | 580-650 |

Key Benefits

>4X

Service life imporvement

25%

Decrease in Grinding Cost

1.5 Tons

Co2 savings per ton of composite casting used

50%

Reduction in maintenance & downtime cost

Success Stories

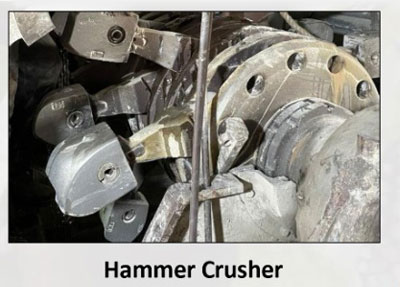

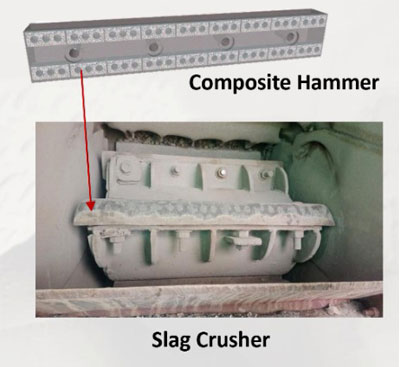

1) Slag Crusing

- Plant location: Maharashtra

- Industry: Recycling

- Wear Part: Slag Hammer

- Raw Material: Ferrous Slag

| Wear Part | Service Life (in Hrs) |

|---|---|

| Previously used casting | 120 |

| Composite Slag Hammer | 730 (6x) |

Service Life Improvement > 6x

Decrease in Slag Grinding Cost ~ 30%

2) Limestone Crushing

- Plant location: Jharkhand

- Industry: Iron & Steel Plant

- Wear Part: Beater Head

- Raw Material: Dolomite / Limestone

| Wear Part | Service Life (in Hrs) |

|---|---|

| Previously used casting | 1440 |

| Composite Slag Hammer | 5860 (4x) |

Service Life Improvement > 4x

Decrease in Slag Grinding Cost ~ 35%